If you sell stock (inventory) in your business, this is how you make money

You can argue that your staff is your most important asset, a new shiny bigger premises will attract more customers, improved financial management will grow margins, etc etc. But you don’t sell any of these. Sales is money and you sell your stock. It is therefore a priority that you give your stock the respect it requires as you have paid to place it onto the shelf its currently sitting on, regardless of if it’s selling or not. So lets discuss how it can be better managed. I acknowledge that yes, staff advise customers as to the type of product, and yes customers will have a pleasant experience in your new shiny store, but at the end of it all, if they want a certain product, you must have it in order to sell it. In this series of 3 articles I will endeavour to outline how to manage your stock as efficiently as possible.

Before we start on this journey, it is important that we provide a health warning and outline that we are speaking here on general terms. A suggestion may/may not be suitable for your exact business requirements but it is, in general a method for working forward to achieving best practice, and the holy grail of stock control – stock levels on your Point of Sale (POS) system that are correct and trustworthy. I hope to achieve two things with you in these articles and assist you;

- in how to achieve optimal stock levels

- have your internal systems optimised

In these three articles we will outline;

- Before you start – the plan

- What to do first – how do you eat an elephant?

- Best practice – tweak and optimise

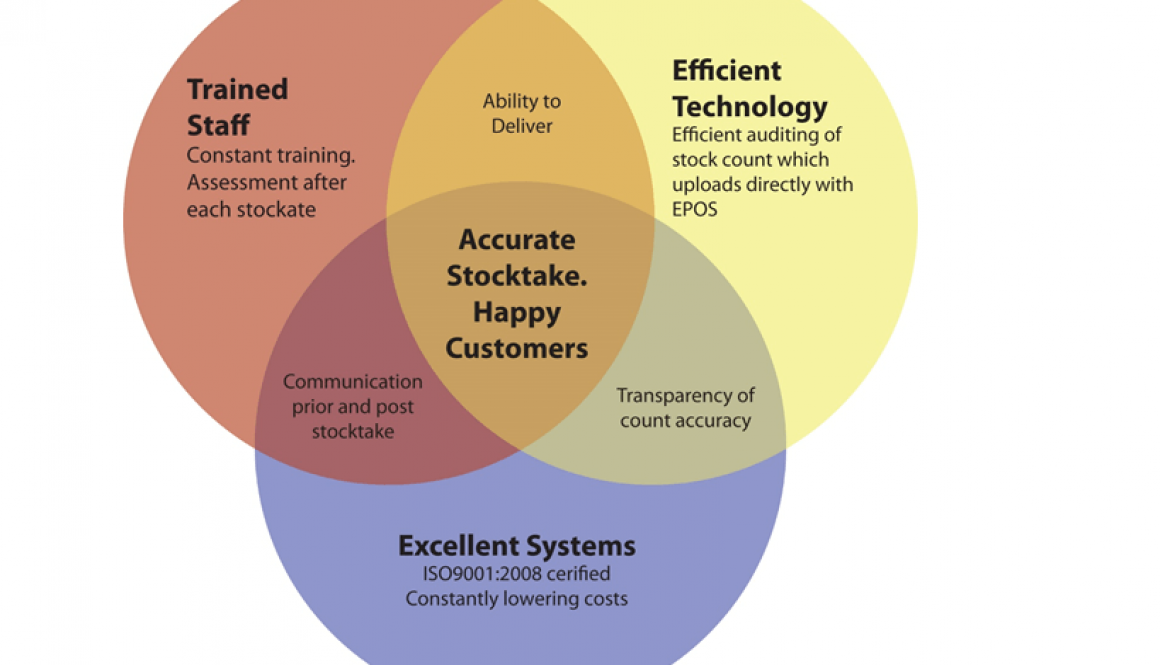

Although my company delivers stocktakes, lets start by saying, a stocktake is not the starting point. it is a point in the future that you must work towards. All too often, businesses think that by having a stocktake their stock control is now in order. It’s not. In a lot of cases it is a process of satisfying the “accountant” who requires a year end valuation of stock for financial reporting. A dreaded process that creates procrastination and fear and “is it that time of year again?” response.

Where we want to get to is by having stock so well managed, then when you run the report on your POS, you know that the figure is correct as you have the internal processes to back it up and keep it constantly updated. So what are those internal processes and how can they be implemented? Before we go there, we must first look at why stock control in hardware premises doesn’t work. In a nut shell, the main reasons efficient stock control does not happen is because of inefficient systems around;

- ordering/purchasing

- receiving/storage

- selling

Within each of the above, there are several reasons that these do not work and almost always come down to

- no systems created

- poor communication

- management not willing to implement change

- inefficient staffing levels

- staffing who are comfortable in doing things “their own way” or are set in their ways

- too busy

- poor knowledge of IT system

- involving too many staff

- no rechecking of accuracy

- selling similar items incorrectly

Your starting point is deciding what does efficient stock control look like for your business? This is your goal for your business and only you can decide it. It could be live stock onto your POS, it may be to have parts of your yard stock on the system as this is your highest value item areas, it maybe your paint section that you want to have a full product range fully available. You decide. To achieve this goal, you must have a plan, with a date of completion as to when the goal will be achieved. You will then set milestones for the future on what you will achieve, who will achieve it, and when. Before you start going hell-for-leather in tidying store rooms, barcoding product, and possibly repeating failed systems of the past, you should consider;

- what is the current level of confidence that I currently have in the stock on my PoS being correct? and why? discuss with your team

- Is it barcoded, correct cost/retail price, correct margin, SKU number, on the system at all?

- Staffing – who can/will over see this project? 1 person who is accountable. What challenges are they likely to receive. Can they deliver?

- IT – is my current PoS system fit for purpose? what do I use it for? can it operate a system that will deliver my goal? Can my team use it?

Think about the above ahead of the next article, where we will discussing how we go about creating systems that last, and how to communicate them with your team, for if they are not on-board, then you could be fighting a losing battle.

Patrick McDermott is Managing Director of Stocktaking.ie, Ireland’s leading provider of outsourced stocktaking services, and CEO of EasyCount – counting software for non-barcoded products

Still want to count your stock in-house? Try DigiTally!

- Digital Stocktakes

- Eliminate pen, paper, Excel and double entry

- Reduce stocktaking time by 66%

motions

motions ive event is a great way to get the attention of clients and prospects. This could be just social like a barbecue or a Christmas party, or structured around business development such as a launch of a new product or promotion. Holding a live event opens up opportunities to meet with potential customers and offers the opportunity for them to experience the look, feel and personality of your brand. Consider raising funds for charity at your event or adding a theme to your event to add some spice or give back and do something good.

ive event is a great way to get the attention of clients and prospects. This could be just social like a barbecue or a Christmas party, or structured around business development such as a launch of a new product or promotion. Holding a live event opens up opportunities to meet with potential customers and offers the opportunity for them to experience the look, feel and personality of your brand. Consider raising funds for charity at your event or adding a theme to your event to add some spice or give back and do something good.